The project

Because of its continuous production process, Trinseo requires the hydraulic installation to be available 365 days a year. Interruptions cost money, after all, especially if there are still liquids in the reactor pressure vessels. If there is a sudden installation failure these liquids could damage the reactor. The other challenge for the Hydrauvision engineers is to create an explosion-free environment.

Our approach

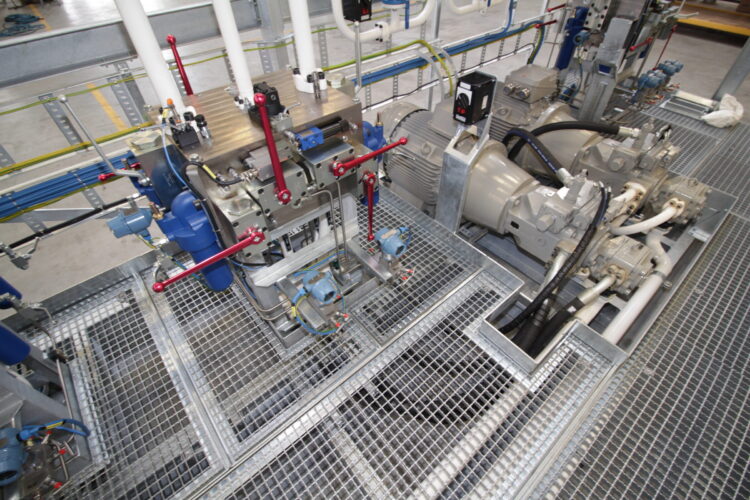

Hydrauvision takes care of the entire engineering, production and installation process for the hydraulic installation. Hydrauvision Piping installs the piping, and Hydrauvision Services is in charge of commissioning. To prevent unwanted failure, the drive system is fully redundant. This means that the system comes with backups for all pumps, the container, coolers, sensors and some of the piping. In addition, various sensors provide a high level of monitoring. This ensures that wear and tear is detected early so it can be placed on the maintenance schedule. The system complies with the current ATEX directives, which means it can be used safely in explosive atmospheres.