The project

Over the past few years, we have expanded our expertise in the field of electrical drive and control technology. As such, Technotron, Electrauvision and Global Electrical Solutions are now part of the Hydrauvision Group. With this expertise in house, we decided to start working on the electrification of Fundex Equipment‘s foundation machines. This led to the development of the F4800E; an all-electric multi-purpose foundation machine.

The F4800E is based on Fundex Equipment’s diesel-powered F4800 foundation machine. This machine has a drilling torque of 500 kNm and a daily energy consumption of up to 2000 kWh. With a 48-meter leader, the electrification of foundation machines of this size is unprecedented, making powering such a large machine the primary challenge. We developed an innovative approach to power supply to ensure that a large foundation machine can keep running throughout the working day.

Our approach

All departments within Hydrauvision were involved in the project.

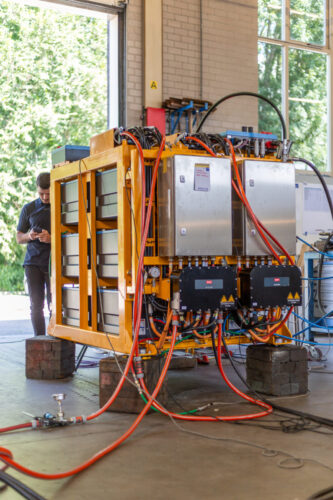

The control cabinets, control panels and DC panels were built at Technotron. The electrical drives were developed by Electrauvision and based on Danfoss Editron components. The various Hydrauvision establishments also each made their own contribution. For example, the pump sets were assembled in Schoondijke and the hydraulic piping was made in Yerseke. The battery pack and generator were assembled in Raamsdonksveer and the valves in IJmuiden.

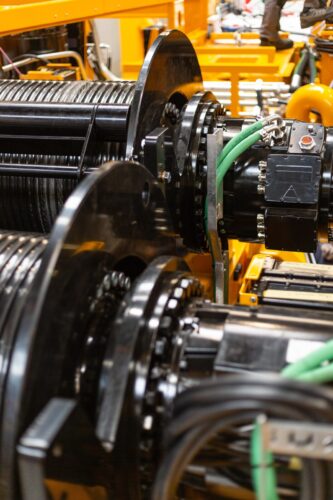

The battery pack acts as an energy buffer. It is capable of absorbing power peaks (peak shaving) and also stores energy that is recovered in the event of winch recoil or braking movements, among other things. The winches are directly electrically driven. Other functions, such as levelling the machine, driving the tracks and moving the leader, are hydraulically driven. The hydraulic pumps, of course, are again electrically driven.

One of the big challenges at the moment is what will be the main energy source of the future. We therefore chose a DC generator with diesel engine to charge the battery pack for this machine, which can currently be used to work anywhere in the world. This configuration preserves the machine’s sustainability advantages by reducing energy consumption by 25-40%, depending on the foundation process. The generator can be easily disconnected and replaced with an energy source running on hydrogen, formic acid or e-methanol, for example. The machine can also be connected directly to the electric grid.

The F4800E’s controls are identical to those of the conventional machine, meaning that operators can easily switch to the electric equipment. Thanks to the electric motor, the machine also makes 90% less noise than a diesel machine, which is a valuable advantage when working in urban environments.

Future proof

On the Canvas Living housing project in Rotterdam, the F4800E successfully installed more than 250 foundation piles. On the same project, a conventional F3500 foundation machine was used as a comparator for the electric machine. Powered by the electric drive system and DC generator, the F4800E proved to be a reliable machine that can match the performance of conventional foundation machines. The additional benefits of the F4800E, namely reduced energy consumption and noise pollution, also showed that the innovative machine was a worthwhile investment.

Commenting on the success of the F4800E to date, Michiel Wondergem, R&D Engineer at Hydrauvision, said:

“The successful performance of the F4800E on the project carried out by Heijmans in Rotterdam is a big step towards the future. It proves that, also in the construction sector, sustainability and high performance can go hand in hand.”